The size of stepper motors plays a crucial role in their effective utilization. Stepper motors are widely used in various industries for precise motion control applications. Understanding the different sizes available and their implications is essential for optimizing performance and achieving desired outcomes.

Understanding Stepper Motor Sizes

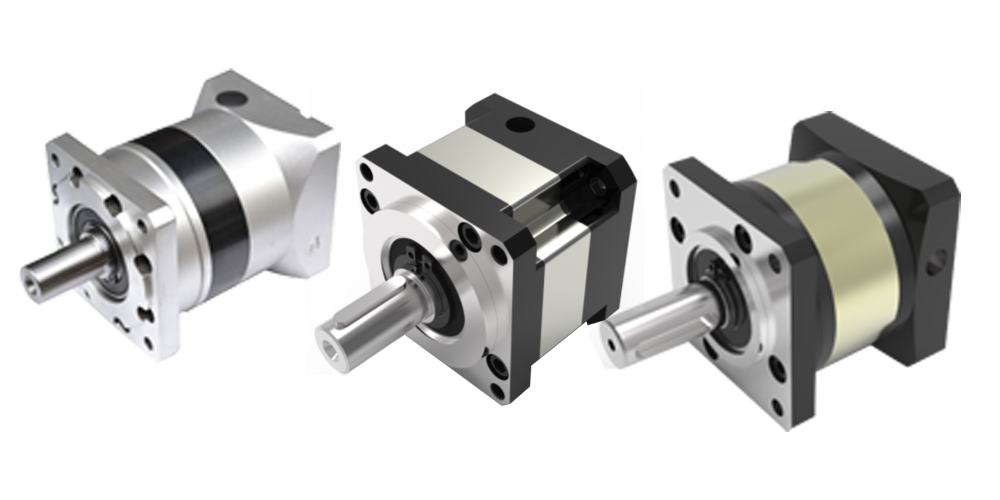

stepper motor sizes refer to the physical dimensions and specifications of these devices. They are typically categorized based on frame size, such as NEMA 17, NEMA 23, or NEMA 34. Each size has its own unique characteristics that determine its torque output, speed capabilities, and overall performance.

Choosing the right stepper motor size is vital to ensure efficient operation within specific application requirements. A larger motor may provide higher torque but could be unnecessary if it exceeds the load demands, resulting in wasted energy consumption. Conversely, an undersized motor may struggle to deliver sufficient power leading to compromised precision or even failure under heavy loads.

The Advantages of Leadshine Closed Loop Stepper Motors

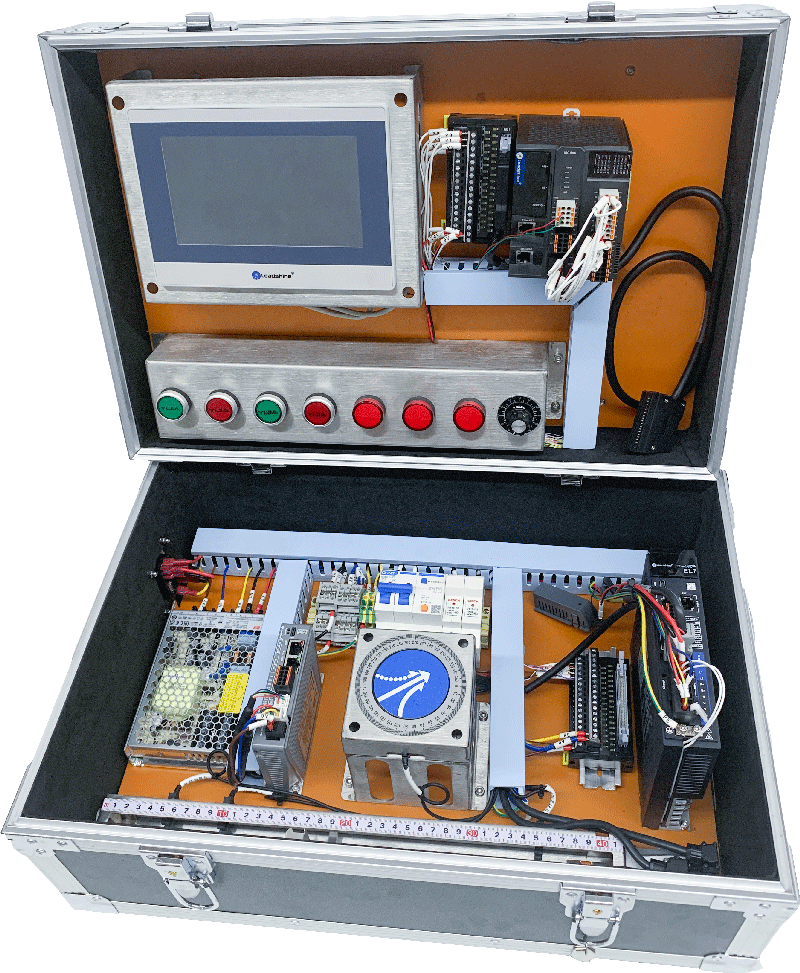

In recent years, leadshine closed loop stepper motors have gained popularity due to their advanced control systems that offer enhanced accuracy and reliability compared to traditional open-loop designs.

Leadshine closed loop stepper motors utilize feedback mechanisms such as encoders or resolvers that constantly monitor rotor position during operation. This real-time feedback enables them to correct any missed steps or errors automatically without relying solely on open-loop assumptions. As a result, they can maintain precise positioning even under varying loads or external disturbances.

Precision Motion Control with Stepper Motors

precision motion control is a critical requirement in many industrial applications where accurate positioning and repeatability are paramount. Stepper motors excel at providing this level of control due to their inherent ability to move in discrete steps, allowing for precise positioning and synchronization.

By selecting the appropriate stepper motor size and pairing it with a suitable driver/controller, precision motion control can be achieved. This enables applications such as 3D printers, CNC machines, robotics, and automated systems to perform intricate tasks with high accuracy and reliability.

Conclusion

In conclusion, understanding stepper motor sizes is crucial for maximizing their effective utilization. Choosing the right size ensures optimal performance while avoiding unnecessary energy consumption or compromised precision. Additionally, leadshine closed loop stepper motors offer advanced control capabilities that enhance accuracy and reliability. When combined with precision motion control requirements in various industries, stepper motors prove to be indispensable tools for achieving desired outcomes.